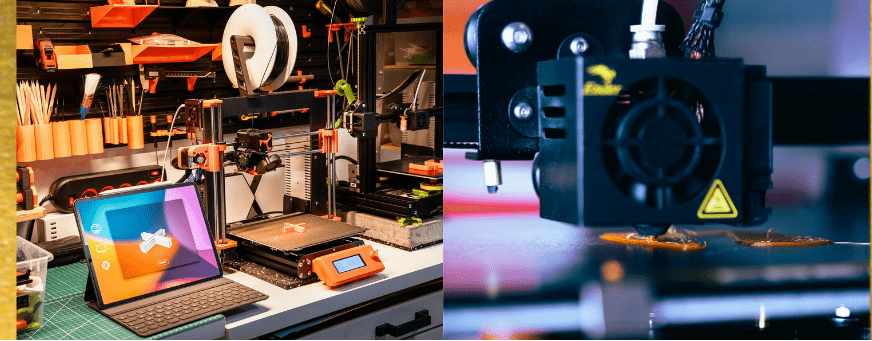

It, otherwise called additive manufacturing, has upset how we approach configuration, assembling, and, surprisingly, regular critical thinking. This innovation empowers us to make three-layered objects from advanced documents, building them layer by layer with unmatched accuracy. Whether you’re a fledgling investigating this entrancing world or an accomplished proficient looking for cutting-edge information, this complete aide is here to help.

What is 3D Printing?

It is a cycle that creates real items from an electronic design by layering resources. Different from conformist collecting strategies that include removing an overabundance of material, 3D printing adds material layer by layer, taking into consideration more complex plans and decreased waste. The innovation has applications in various ventures, from medical services and cars to form and aviation.

How Does 3D Printing Work?

It process begins with a digital 3D model, normally made utilizing PC Helped Plan (computer-aided design) programming. This model is then cut into slender even layers by cutting programming. The 3D printer adheres to these guidelines, constructing the article layer by layer from the picked material until the whole design is finished.

The 3D Printing Workflow:

1. Designing: Using computer-assisted design encoding to make a 3D model.

2. Division: Changing the model into coverings and generating the G-code orders for the printer.

3. Printing: The 3D printer adheres to the directions and constructs the item layer by layer.

4. Post-Processing: Tidying up, sanding, or completing the printed object depending on the situation.

Sorts of 3D Printing Technologies

Understanding the different 3D printing technologies is fundamental to picking the right one for your requirements. Here is an outline of the most famous sorts:

1. Fused Statement Displaying (FDM)

– Materials Used: PLA, ABS, PETG, TPU.

– Applications: Prototyping, producing, and instructive purposes.

– Advantages: Savvy, reasonable for fledglings, and offers a large number of materials.

– Disadvantages: Lower goal contrasted with different innovations, apparent layer lines.

2. Stereolithographic (SLA)

– Materials Used: Photopolymer tars.

– Applications: Dental models, adornments, and point-by-point models.

– Advantages: High goal and smooth surface completions.

– Disadvantages: Pitch can be untidy and requires post-handling.

3. Selective Laser Sintering (SLS)

– Materials Used: Nylon, glass-filled nylon, and adaptable plastics.

– Applications: Utilitarian models, aviation, and car parts.

– Advantages: No requirement for help structures, sturdy and utilitarian parts.

– Disadvantages: Costly and requires proficient taking care of.

4. Digital Light Handling (DLP)

– Materials Used: Photopolymer saps.

– Applications: Dentistry, gems, and profoundly definite models.

– Advantages: Quick printing velocities and high goal.

– Disadvantages: Restricted material choices, require post-handling.

Materials Utilized

Picking the right material is pivotal for accomplishing the ideal properties in your result. Here is a once-over of the most normally utilized materials:

1. Thermoplastics (ABS, PETG, Nylon)

– ABS: Solid, heat-safe, ideal for utilitarian models.

– PETG: Solid, adaptable, and impervious to influence.

– Nylon: Adaptable, solid, and impervious to scraped area.

2. Saps (Standard, Extreme, Adaptable)

– Standard Resins: Appropriate for nitty gritty models with smooth completions.

– Intense Resins: Intended for utilitarian and mechanical parts.

– Adaptable Resins: Ideal for delicate, elastic-like items.

3. Metals (Tempered Steel, Aluminum, Titanium)

– Used in modern applications, offering assets and hardness.

4. Composites (Carbon Fiber, Glass Fiber)

– Gives improved strength and firmness, utilized in elite execution applications.

Utilizations of It

The flexibility of It has encouraged its greeting through different initiatives. Here are a few striking applications:

1. Prototyping and Item Development

3D printing empowers quick prototyping, permitting originators and architects to make quick and financially savvy prototypes. This speeds up the item advancement process, empowering iterative testing and development.

2. Medical care and Clinical Devices

From making customized inserts and prosthetics to creating careful models, 3D printing is changing the medical services industry. It offers the capacity to personalize clinical treatments and make patient-explicit arrangements.

3. Car and Atmosphere

3D printing is broadly utilized in the manufacturing of car parts and aviation components. It takes into account lightweight plans, decreasing general weight and fuel utilization while guaranteeing high strength and durability.

4. Engineering and Construction

Draftsmen utilize 3D printing to make scale models of buildings and complex designs. This innovation considers unpredictable plans and gives an unmistakable portrayal of design ideas.

5. Style and Jewelry

The style business benefits from customizable designs, empowering the making of special attire, extras, and adornment pieces that were once difficult to produce.

Advantages of 3D Printing

1. Cost-Efficiency

3D printing disposes of the requirement for costly tooling, diminishing manufacturing costs essentially. It’s particularly savvy for short creation runs and handcrafts.

2. Plan Flexibility

Customary assembling processes have restrictions regarding plan intricacy. Conversely, 3D printing offers unlimited plan possibilities, taking into account the formation of complex calculations.

3. Quicker Creation Times

With 3D printing, production times are essentially reduced. This innovation empowers quick prototyping and abbreviates an opportunity to market items.

4. Sustainability

3D printing produces less waste than conventional assembling strategies, making it a more naturally friendly choice. Moreover, it upholds the utilization of recycled materials, adding to a practical creation cycle.

Difficulties and Limits of 3D Printing

Despite its various benefits, 3D printing has specific impediments that should be thought of:

1. Restricted Material Options

Contrasted with customary assembling, the scope of materials accessible for 3D printing is as yet restricted, particularly for high-strength or high-temperature applications.

2. Post-Handling Requirements

Numerous 3D-printed objects require post-handling, for example, sanding, painting, or curing, to accomplish the ideal completion. This can add time and work to the cycle.

3. Print Speed

While 3D printing is quicker for prototyping, it very well may be slower for huge-scope production, making it less appropriate for mass assembling.

4. Quality and Accuracy

FDM prints, specifically, may show noticeable layer lines, requiring extra post-handling to accomplish a smooth completion. Accomplishing high accuracy and quality can be trying for specific plans.

Ways to begin with 3D Printing

Assuming that you’re prepared to investigate the universe of 3D printing, here are some tips to assist you with getting started:

1. Start with a Novice Accommodating 3D Printer: Pick a printer that is not difficult to set up and work, like those that utilize FDM innovation.

2. Learn the Nuts and bolts of computer-aided design Software: Get to know famous computer-aided design programs like Tinker CAD or Fusion 360 to make your plans.

3. Experiment with Various Materials: Start with PLA fiber and continuously investigate different materials to track down the best fit for your activities.

4. Join 3D Printing Communities: Drawing in with online networks can give significant bits of knowledge, tips, and investigating guidance from experienced clients.

Conclusion

3D printing is a game-changing technology that offers vast potential outcomes across different enterprises. Whether you’re keen on prototyping, producing, or just making extraordinary items, understanding the basics of 3D printing can open endless doors. As innovation keeps on advancing, it’s turning out to be more available and flexible, making now the ideal opportunity to plunge into the universe of 3D printing.

218GB PREMIUM Studio HD Videos FORUM TORRENT

ONION LINKS FOR TOR 2024 PEDOPHILES KIDC CP FREE VIDEO

218GB MAGNET LINK FOR TORRENT CLIENT (ADD URL) magnet:?xt=urn:btih:abd5aaed52b5994fe54136701c4c18156bd28415

WEBSITE: OPEN IN AN ANONYMOUS TOR BROWSER LINK: http://www.torx5mtxatfovjmdizm27tsqusa4bgej5qx7zvv2quxvh44spl5xzsad.onion